Faucet leaks are the nuisance of bathroom maintenance issues.

And the cost can be high. A leak that loses just one drop per second can waste up to 3,000 gallons of water a year.

Sometimes leaky faucets are a quick fix, but other leaks can prove more difficult and come back over time.

To get started diagnosing and fixing a leak, it’s essential to know what type of faucet you have and how it’s designed.

Before you begin any maintenance, be sure to shut off the water to the sink. This will mitigate the risk of water flooding the sink while you are trying to handle your repairs.

Ceramic-disk Faucets

Ceramic-disk faucets are a recent innovation in the world of faucet design. If you have a newer faucet, there’s a good chance it’s a ceramic-disk faucet.

Disk-faucets have a wide-cylindrical stem, with a single lever to regulate water perched above the stem. The faucet head branches off from the cylindrical stem.

With this faucet, hot and cold water are mixed inside the pressure balance cartridge, and water volume is regulated through two ceramic disks below the cartridge that rise and fall.

The handle is moved side-to-side to adjust the temperature of the water.

To repair a ceramic-disk faucet, first remove the set screw, which can be accessed by pushing back the faucet handle. Proceed to unscrew the escutcheon cap and mounting screws, and then you can lift out the cylinder stem.

Next, remove the neoprene seals with a blunt screwdriver. These seals may be damaged and require a replacement, but if they are still intact, you may clean them with distilled white vinegar and a plastic scouring pad.

After rinsing the seals thoroughly, you may reattach everything and test the faucet.

Ball-type Faucets

Ball faucets get their name from the faucet handle being placed over a rounded ball-cap, instead of a simple lever. This allows for a wide range of movement. These are commonly installed in kitchens.

In a ball faucet, the ball-lever assembly regulates water volume and mixing temperature, and they have a single lever.

These faucets are often more challenging to repair because they have so many parts. Usually, your best option is to buy a replacement “kit” and install the new part.

Begin by unscrewing the handle set screw and remove the handle. Next, remove the cap and collar with pliers.

Use the tool included in the replacement part kit to loosen the faucet cam, and then take out the cam washer and rotating ball.

Next, take off the inlet seals and springs with pliers, and cut the o-rings.

Coat the new o-rings in plumber’s grease and roll them on to install. Finally, put in the new springs, valve seats, and cam washers to reassemble the faucet.

Cartridge Faucets

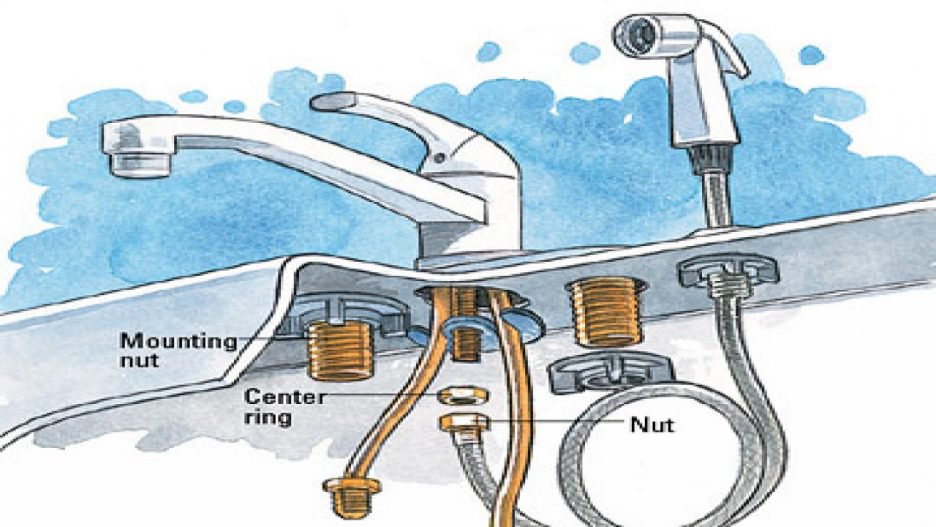

There are two types of cartridge faucets: the single-handle variant (pictured), and the double-handle option.

The single-handle variants use a stem cartridge that moves up and down to adjust the flow of water. To change temperature, the handle is moved side-to-side.

A double-handle cartridge faucet looks similar to a compression faucet. The main difference is that, on a cartridge faucet, handle movement is smooth and consistent and only requires a slight turn. (A compression faucet will tighten when you turn it further, as it needs to squeeze the washer to stop the flow of water.)

To repair a leaky cartridge faucet, begin by removing the handle. You may also need to use pliers to remove the cartridge retaining clip. (However, these are not always present in a cartridge faucet.)

Next, you can pull the cartridge up and out of the faucet. Cut the o-rings and remove the faucet’s spout (these are what lead to faucet leaks in compression faucets).

Installing new o-rings is simple. Coat them in plumber’s grease and reassemble the unit. If the cartridge also needs to be replaced, make sure the replacement is the same length and compatible with your faucet.

Compression Faucets

Compression faucets have been around a long time and are primarily found in older homes.

While they are relatively inexpensive, they are the most leak-prone. Compression faucets have two handles – one to regulate hot water and the other to adjust cold water.

The handles are simply tightened to stop water from flowing. A screw and washer combination (known as a compression stem) is tightened by the handles to stop the flow of water against a seat valve.

The cause of a leak on a compression faucet is usually worn-out seat washers.

To replace them, remove the handle and unscrew the packing nut with a crescent wrench. Next, find the brass screw holding in the seat washers and unscrew it to remove them.

Coat the new washers in plumber’s grease and then replace the o-rings, as they are often faulty as well. Before installing new o-rings, make sure they match the old ones in size and coat them in plumber’s grease.

Reassemble everything, and you should be good to go.

Experiencing difficulties dealing with a leaky faucet? Contact the experts at Agentis. We’re ready to tackle any project you can throw our way.